- ‘A’ shaped structured column with multiple cross ribs offers high cutting performance.

- Extra Wide base offers very higher stability for big size jobs during heavy duty machining.

- LM Roller Guideways for all 3 axes provides higher cutting dynamics and longer machine life.

- Imported spindles from Taiwan with G1 balanced grade offers superior finish up to 0.45Ra Value.

- Controller options with latest configuration from Mitsubishi and Fanuc available.

- 10,000 rpm spindle with ceramic bearing results in machining of all precision jobs and longer spindle life and hence higher finish quality.

- High efficiency and productivity can be ensured with Fred rate of 10,000mm/min and rapid feed rate of 36 m/min.

- X axis LM Roller Guideways has 6 shoes to provide uniform stability for bigger jobs machining.

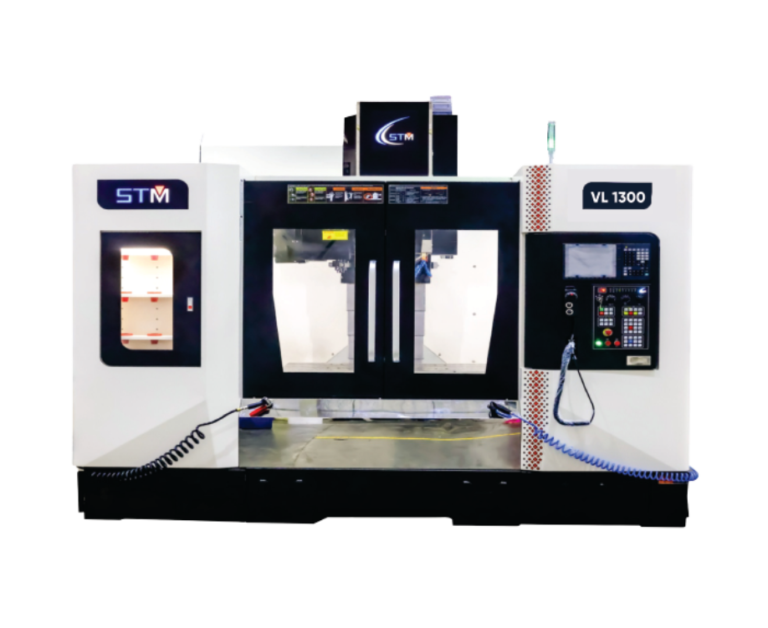

| Model | VL 1300 |

|---|---|

| Travel | |

| X / Y / Z travel | 1,300/700/700mm |

| XYZ ballscrews | C3 40mm |

| Spindle nose to table surface | 120 – 820mm |

| Spindle center to column surface | 700mm |

| Table | |

| Table size | 1,450 * 640mm |

| T slot ( Size / Qty / Dist. ) | 18mm x 5 x 140mm |

| Max. table load (Kgs) | 1,500kg |

| Spindle | |

| Speed | BT40-8,000rpm Belt (Opt:10,000rpm ) BT50-6,000rpm Belt |

| Transmission | Belt Type |

| Guide ways type | LM Roller |

| Feed Rate | |

| Rapid feed rate of XYZ Axis | 30/30/24m/min |

| Cutting feed rate | 1-10,000mm/min |

| Accuracy asper VDI – DGQ – 3441 | |

| Position accuracy | ±0.005 |

| Repeatability | ±0.003 |

| Automatic Tool Changer | |

| Tool storage capacity | Arm 24T ATC |

| Max. tool diameter(Arm Type) | Full: 80mm Next empty : 150mm |

| Max. tool length ( Arm Type) | 300 mm |

| Max. tool Weight ( Arm Type ) | 8kg |

| CNC Controller & Motor | |

| CNC controller | Mitsubishi M80 |

| Spindle motor | 11/15 ( Opt: 15/18.5 )kW |

| Axis motor X,Y,Z | 3.5/3.5/4.5 kW |

| Coolant | |

| Pressure | 10kg/cm² |

| Coolant pump | 0.75HP |

| Coolant tank capacity | 300L |

| Air & Power Supply | |

| Air source | 5-7kg/cm² |

| Power supply | 25kVA |

| Machine Size | |

| Machine dimensions (L*W*H) | 3,950 x 2,780 x 2,860mm |

| Machine net weight (approx) | 8,500Kg |

- Full Guarding

- Rigid Tapping

- Coolant Pump

- Transformer

- Handwheel

- Panel AC

- Auto Lubrication

- Halogen Work Light

- Signal Lamp

- Coolant Gun

- Air Gun

- Head Coolant

- Cutting Air

- Spindle Air Blast

- Tools Box

- Manuals

- USB/RJ45/RS232 Interface

- ECB

- Fanuc Oi-MF/Siemens 828D SL

- Spindle Chiller

- 20 Bar Coolant Through Spindle

- 16/20T Armless ATC

- 200mm Raiser Block (on select models)

- TPM

- 20/24T Arm Type ATC

- Flush Coolant

- Scrapper Type Chip Conveyor

- Screw Type Chip Conveyor

- Dual Type Chip Conveyor

- Automatic Grease Lubrication

- Oil Skimmer

- 4th Axis Cable Preparation

- 4th Axis Rotary Table

- Automatic Tool & Workpiece Measurement

- CE Safety

Machine Type

Share on facebook

Share on linkedin

Share on email

Share on whatsapp

Application Sectors

No data was found